DYEING

A complete range of dyeing solutions

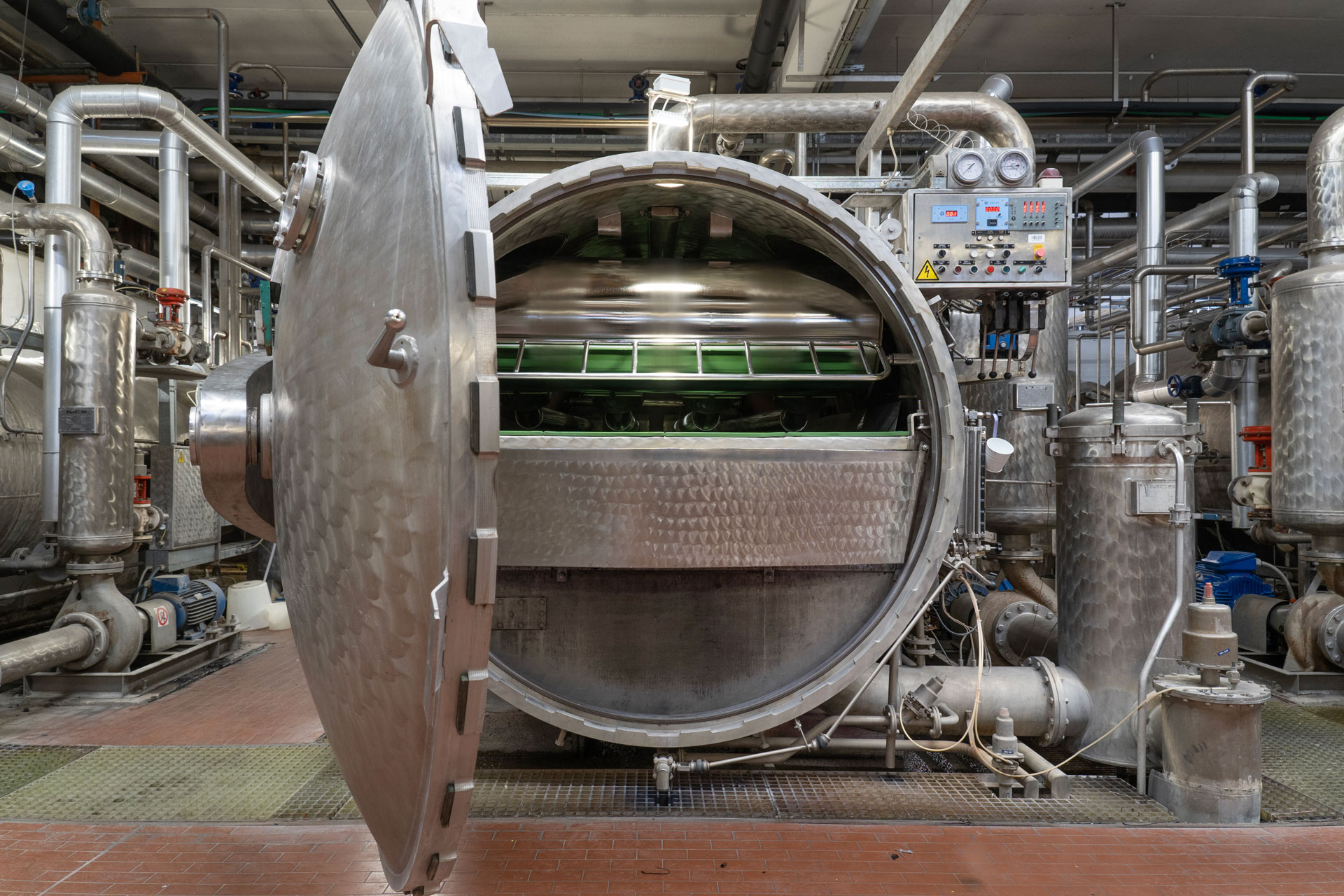

The Tintoria Finissaggio 2000 dyeing plant in Masserano (Biella) meets the strictest environmental protection standards.

New-generation technology and our technical know-how, knowledge of various different fibres and profound perception of our customers’ desires qualify us to dye fibres of all kinds. In addition to it, what makes the difference in our dyeing plant is the experience of our personnel and their orientation toward achieving perfect results. We pay the utmost attention to details and hues, to timing and processes: essential features for creating the undeniable intrinsic value people now expect from a product made in Italy.

Along with our consolidated experience in dyeing prestigious natural fibres such as wool, cashmere, silk, linen and cotton, we also work with cellulose fibres such as viscose and technical and synthetic blends made with polyester, polyamide and aramid fibres.

The added value we offer to our customers includes:

REPEATABILITY

Accurate REPEATABILITY of the colour in different dyeing batches

FLEXIBILITY

and the possibility of dyeing anything from samples and small batches ranging from 5 metres to 400 kg industrial batches.

ORIENTATION

toward meeting the customer’s requirements, colours customization and consulting services aimed at achieving the desired results

Dyeing plant: our processes

The specialised services and treatments we offer in our dyeing plant include:

SPECIAL PREPARATION

treatment permitting brilliant colours and excellent yield, particularly on wool and cashmere

SPECIAL DYEING

a dyeing process guaranteeing high levels of colour solidity, which we have developed through targeted research. Ideal for Total Easy Care wool, treated to limit felting.

SUPERWHITE

a treatment for wool and cashmere achieving hues of white comparable to those obtained on cotton, without altering the of the fabric.

FLUO COLOURS

an explosion of brilliant colours with excellent performance in terms of solidity. Appropriate for all kinds of apparel, from sportswear to fashion, safety garments and high visibility workwear.

DÉLAVÉ EFFECTS

dyeing to create a mottled effect, possibly with two colours, on wool and cashmere, ensuring the repeatability of the colour and the quality of processing without altering the nature of these noble fibres.

MOTTLED DYEING

A dyeing process producing a mottled final effect on the fabric. The reserve dyeing technique can achieve a variety of different results creating varying hues of colour.