QUALITY CONTROL

Quality control, a guarantee for our customers

“You get what you measure… It’s hard to get what is not measured!”“

Quality control is the “yardstick” of the standards we work with. It allows us to guarantee that our customers get a product that meets their expectations, and it is in line with our values of taking extreme care of every aspect of processes.

We conduct physical and mechanical tests and use inspection machines in our own in-house laboratory, applying the standards required by each one of our customers.

Step 1

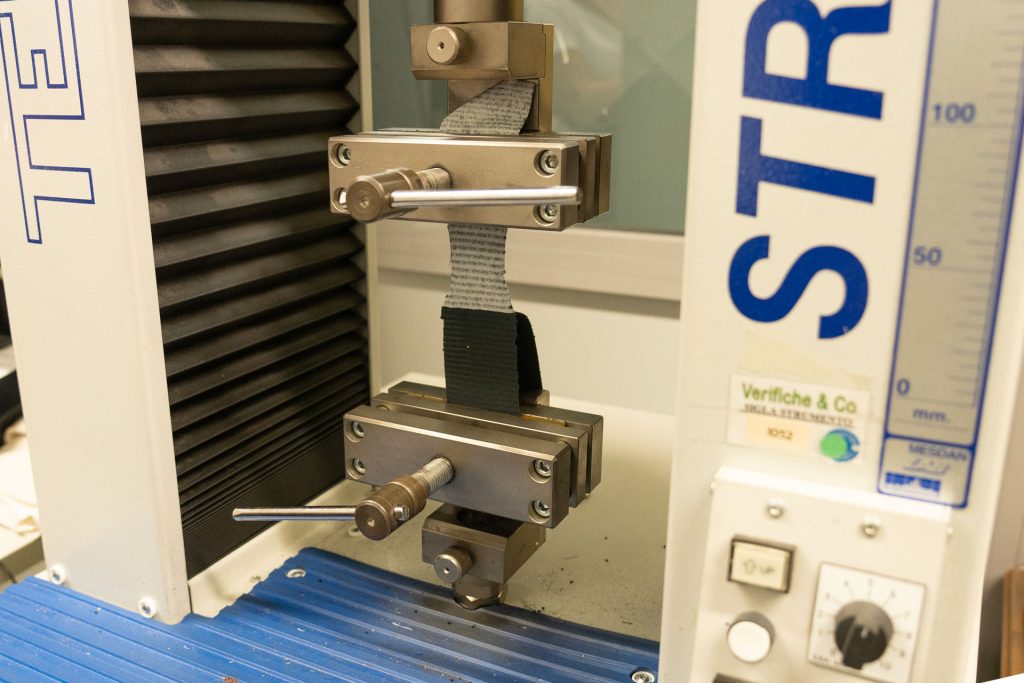

laboratory tests to check the conformity of the processed fabrics. Though our in-house laboratory is not certified, we apply globally recognised standards to all the tests we perform:

- Dimensional stability following steaming and washing

- Water repellence and oil repellence

- Dynamometric tests (tensile stress, breaking load, elongation)

- Colour tone test

- Colour solidity (GB/OEKOTEX)

- Martindale (abrasion and pilling)

- Look and feel tests

- In the case of laminated articles: delamination with dynamometer, breathability and waterproof rating when laminated with membrane

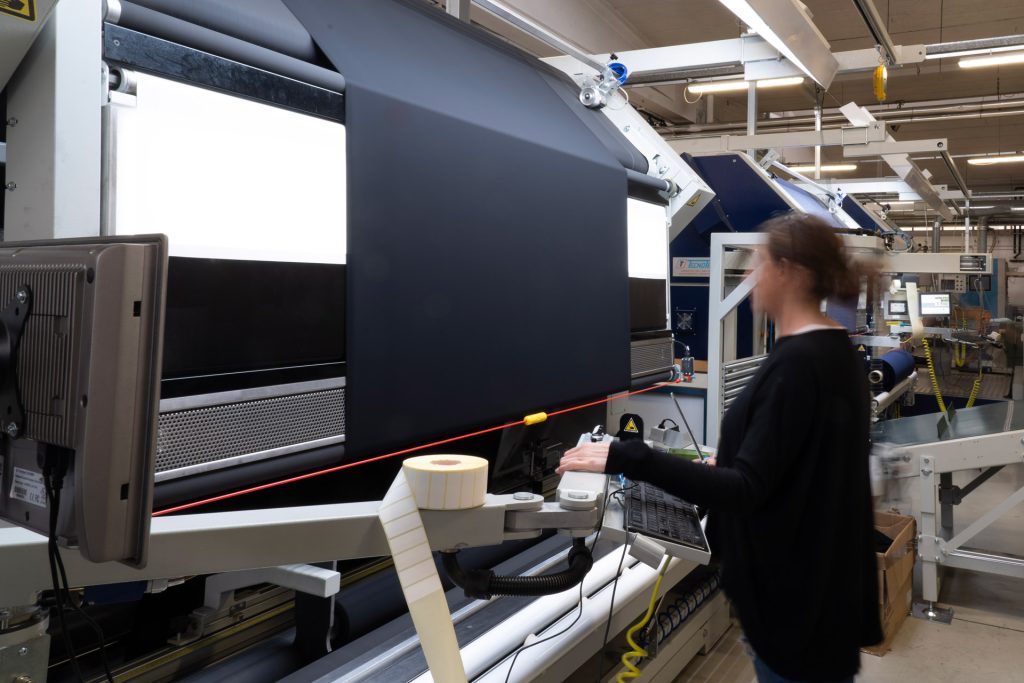

Step 2

having undergone the check of conformity in our laboratory tests, bolts of cloth are now inspected to complete their quality control. The homogeneity of each bolt of fabric is determined on the basis of the following parameters:

- Height

- Gram weight

- Length

- Defectiveness

- Look/feel

- Straightness of threads

Upon conclusion of these inspections, the bolt of fabric may be wrapped for shipping

The importance of the human factor in quality control

Quality control is the final step in our processes, characterised by great meticulousness and precision. Our experience and constant striving for improvement make us part of the manufacturing value chain labelled as “Made in Italy”

In addition to our laboratory tests, another factor determining the excellence of our quality control is the fact that inspection is performed by our own personnel.

The sensibility in assessment of fabrics and treatments that our workers have been developing over years and years of work allows our staff to conduct accurate visual and tactile inspections taking into consideration colour yield, the correspondence of hue to the sample, the feel and weight of the fabrics following treatment, and the overall “feeling” the fabric acquires.